Industrial operations depend heavily on the performance and reliability of electrical systems, and among the most critical components is the variable frequency drive (VFD). These drives regulate motor speed and torque, improving energy efficiency and extending motor life.

However, like any equipment, VFDs can degrade over time. Without timely repair, their failure can lead to costly downtime, safety hazards, and reduced productivity.

What is a Variable Frequency Drive?

A variable frequency drive is an electronic device that adjusts the speed and voltage supplied to an electric motor. VFDs enable precise control over motor functions to reduce energy waste and mechanical stress, supporting smoother operations and longer equipment lifespan. They also include control circuitry for feedback, fault detection, and integration with programmable logic controllers (PLCs) and industrial networks.

VFDs are commonly used in HVAC systems, conveyor belts, pumps, and other motor-driven equipment where speed variability is crucial.

The Role of Repair in Equipment Longevity

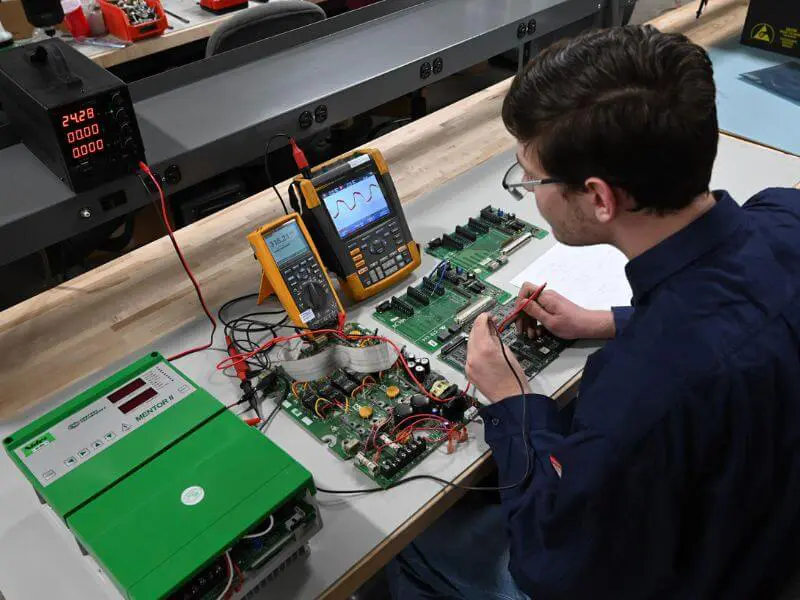

Routine maintenance is essential for all equipment, but variable frequency drive repair becomes critical when warning signs such as overheating, erratic motor performance, or alarm codes appear. Timely repair prevents cascading failures in connected systems and avoids the high cost of full replacement.

Skilled repair services can restore drives to optimal function, recalibrate settings, and replace worn components while maintaining original equipment specifications.

Why Compliance with Safety Standards Matters

VFD repair isn’t just about performance. It is also a key part of maintaining a safe, compliant workplace. Standards like OSHA 1910 and ISO 45001 require that electrical systems be regularly inspected and maintained to reduce the risk fo shock, arc flash, and equipment malfunction. When drives overheat or fail unpredictably, the result can be anything from a line shutdown to a serious safety incident.

Proper maintenance and timely repairs reduce these risks. A well-functioning VFD supports stable motor control, allows for safer emergency stops, and integrates more effectively with modern safety interlocks and monitoring systems.

Boosting Productivity Through Proactive Repairs

Downtime in industrial operations can cost thousands of dollars per hour. Proactive variable frequency drive repair services reduce unplanned outages and contribute to leaner operations. A single VFD failure can stall an entire production line. Prioritizing repairs will help stabilize operations, avoid emergency service calls, and support planned maintenance cycles.

Environmental and Operational Stress Factors

Variable frequency drives are often exposed to harsh industrial conditions, including heat, dust, vibration, and electrical noise. These factors can accelerate wear on capacitors, cooling fans, and circuit boards.

Understanding how environmental stress impacts VFD performance allows for better preventive maintenance and repair planning. For example, facilities with high ambient temperatures may need to closely monitor thermal protection systems or schedule more frequent inspections.

Additionally, drives used in applications with frequent starts, stops, or load variations are more prone to component fatigue. By accounting for these stressors in repair protocols, facilities can improve drive longevity and ensure stable, compliant operations across various conditions.

Driving Reliability Through Repair

VFDs are vital for efficient, safe, and sustainable industrial operations. Regular repairs and adherence to safety standards protects workers and safeguard equipment and production goals. Investing in expert repair services now can save far more in future replacement costs and lost productivity.

To learn more about maintaining and repairing VFDs and how they impact your operations, contact Adam Kahler at akahler@quadplus.com or call (815) 210-9885.

Quad Plus – www.quadplus.com

1379 Unit C Carlson Ave New Richmond, WI 54017