GBIG News

Get links to the latest news, events, stories, and interviews from our 5P news members. Our goal is to remind the decision-makers in Wisconsin of the importance of our industry both historically, and more importantly, into the future.

Read the latest 94 Stories and Links on the Internet below.

Featured Stories

- Georgia abruptly closes 5 paper

- Georgia Abruptly Loses 5 Paper Plants Triggering $2.9 Billion Economic Timebomb

- Patti Habeck named new President and CEO of New North, Inc.

- Wisconsin education teachers attend wood industry course at new training sawmill

- AI already displacement of these jobs

- UW Madison researchers map out a promising future for solvent based plastic recycling

- Wisconsin skyrocketing American tourism.

- UW Madison launching new hub to accelerate entrepreneurship

- Georgia-Pacific leverages retirees expertise to maintain productivity and ensure knowledge transfer

- Proctor and Gamble doubles down forest degradation

- Hamilton Wood Type & Printing Museum announces Beth Kowalski as New Executive Director

- Talk tissue converting with Giambini Managing Director of North America

- UW Stout partner award with Great Northern Corporation

- A largely invisible role of international students fueling the USA economy

- Which Wisconsin companies are best to work for!

- Georgia-Pacific acquires Anchor Packaging

- Timber harvesting in national forests while cutting public oversight won’t solve wildfire problem

- What is the 996 rule in China – Slave labor at the expense of the workers.

- Asia Pulp and Paper China walks back on its 2013 commitment to no deforestation

- Wisconsin Packaging plant to close with 48 employees laid off.

- KDV Label welcomes Joe Daubert as CFO

- Quad Europe rebrands as P/mint

Packaging

- The Most Popular Brand Color in each industry

- Liquid Packaging Market project to grow at 5.2 cagr

- Sustainability legislation drives packaging innovation for recycling

- Sustainable innovation in the flexible packaging can’t wait

- Reusable packaging market size & growth 2025 – 2031

- Paperboard packaging market to reach $347 billion by 2034

- Navigating the new wave of packaging regulations

- Commercial Printing market worth $848 billing with focus on packaging and digital Printing

- Interactive packaging market growth at 6.1% cagr 2025 – 2035

- Sustainable pharmaceutical packaging market set to surpass $316 billion

- SAPPI expands recyclable high barrier paper for packaging

Forest

- The Amazon lost area larger than Spain

- Deforestation linked to thousands of heat related deaths each year

- Deforestation reduces rainfall 74% and increases temperatures 16% in the Amazon

- World scientists may have identified a culprit behind declining amazon rains

- Wisconsin researchers listen to forests to learn to protect them

Education

- UW Madison rated highly for career preparation of graduates

- Fewer Indiana high school college enrollment hits record low

- What goes into University budget and the Impact of Federal funding cuts

- Cornell University restructure due to job cuts Trump administration

- Trump cancels dozens of educational grants with more terminations

- UW Stout graduate students protein packed candy – cheese creations earn accolades

- The Future of American higher education is the global crown slipping from their hands

- Northwestern President resigns with Trump federal funding layoffs

- Humanities and Social Sciences most cut UW programs

- Top Harvard mathematician Liu Jun leaves US for China

- UW Platteville sees 10% increase in freshman class

AI

- ai having a significant impact on young workers prospects

- ai killing entry level jobs

- 45 million jobs at Risk from ai report calls for a modern income stabilizer

- ai pioneer predicts ai could cause 99% of workers unemployed by 2030

- Management in the age of ai

- ai isn’t replacing workers just wasting money

- ai intelligence replace teachers

- ai expanding economic opportunity

- Companies are benefiting from ai driven layoffs

- Open ai is hiring a pilled academics to build a scientific discovery accelerator

- How ai is driving a sharp rise in electricity bills

- ai machine learning for engineering design

Sponsors

- Boldt Co. aims to play active in state’s data center development

- Keller opens a 30,000 square foot steel shop

- Lagers and Loggers fundraisers sponsored by Boldt

- Orin Technologies of Verona chosen to clean up former cliffs dow site

- Andy Knapp Joins Anderson-Vreeland

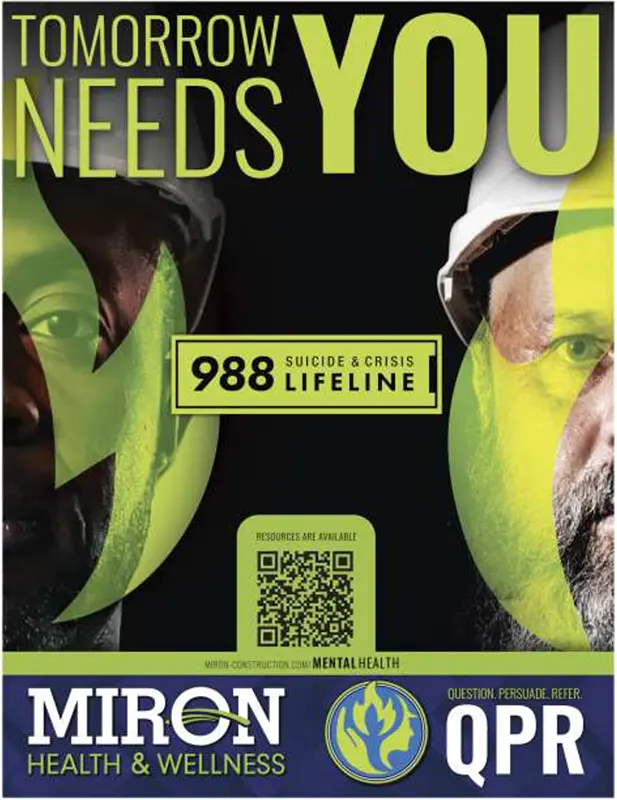

- Miron Construction donates $106,800to 30 local organizations

- Hybrid Software buys artwork management