Read the July 12th, 2023 Green Bay Innovation Group Newsletter here.

Read the July 12th, 2023 Green Bay Innovation Group Newsletter here.

Mark your calendars to check out Cocoon Brewery with us!

Monday, July 17th, 5:30 PM.

Come and network with the ladies of the 5Ps while we sip some brews!

Where: 2233 Kaftan Way, De Pere, WI

RSVP to Cassie – Cassie.Diedrick@robinsoninc.com or

Emily – ehaines27@gmail.com

Helein joins a growing team focused on sustainable coatings, including Jeff Carew, who assumes the role of President, Vireo Coatings Business Unit. Additional leadership changes include the promotion of Martin Rothe to President, Converting Business Unit, and Brian Boulter to Corporate Administrative Manager, Converting Business Unit.

APPLETON, Wis. (June 29, 2023) – ProCon, a premier provider of converting, coating, and paper sales, welcomes Kelly L. Helein as the new Vice President of Business Development. Helein will help bring the latest innovaCon from ProCon, Vireo Coatings, to market.

With a proven track record of leading business development and sales function in multiple industries, including several global paper, packaging and coating companies, Helein brings a wealth of knowledge to drive ProCon’s continued success and growth in sustainable coatings.

She joins an expanded leadership team, including Jeff Carew, a ProCon operations leader and former senior vice president, who was recently promoted to President for the Vireo Coatings Business Unit.

“We are thrilled to have Kelly join our team as our new VP of Business Development,” said Carew. “Her deep industry knowledge and dynamic leadership style make her the ideal candidate to drive our company forward and help launch Vireo Coatings. We believe her addition will further strengthen our position in the market and enhance the value we provide to our clients.”

“I am honored to be part of the ProCon team and to have the opportunity to contribute to the company’s continued growth and success,” said Helein. “ProCon has a remarkable reputation for innovation and client satisfaction, and I look forward to collaborating with the talented professionals here to further elevate our capabilities and exceed customer expectations.”

Passionate about sustainability and the impact of packaging on the global network, Kelly champions change as a Board Member for the University of Maine Pulp and Paper Foundation, Smithers Pira Sustainability in Packaging (EU/US) and Specialty Papers (EU/US), Paper Hall of Fame Nomination Committee, and development committee for the Trout Museum of Art in Appleton, Wis. Helein is a graduate of University of Wisconsin-Madison where she obtained a Bachelor of Arts, International Relations/Foreign Policy.

ProCon recently made additional leadership changes, including the promotion of Martin Rothe to President for the Converting Business Unit and Brian Boulter to Corporate Administrative Manager, Converting Business Unit.

About ProCon:

Progressive Converting (ProCon) was founded in 1991 by an entrepreneurial group of printing professionals who shared a profound understanding of paper, printing, and the demands of mills. Today, ProCon is the largest independent paper converter by market share in the United States and the premier converting and logistics partner for the North American paper industry. With multiple locations and distribution throughout the nation, ProCon provides high-quality converting services and innovative solutions to merchants, commercial printers, and paper mills. The introduction of Vireo Coatings offers a plastic free barrier coating technology to meet consumer packaging sustainability initiatives. For more information, visit pro-con.net.

For media inquiries, please contact: Kelly Helein, 920-243-4272 ext 4272, khelein@pro-con.net

We recognize that the Communist Party of China, The China State Owned Banks, and other Chinese Companies have been buying up CRITICAL KEY ASSETS across the globe dominating the Paper, Pulp, Converting and Forestry industries. Most recently, Paper Excellence significantly increased their global reach expanding to include nonwoven and containerboard. The acquisition positions them to be the 2nd largest nonwoven supplier in the United States! We have attached an overview from Greenpeace for you to review! We recognize that Paper Excellence has responded to the report, saying Paper Excellence is entirely independent of APP/Sinar Mas. We will let you draw your own conclusions.

We will highlight some KEY POINTS from the report.

PAPERING OVER CORPORATE CONTROL: PAPER EXCELLENCES RELATIONSHIP WITH ASIA PULP & PAPER AND THE SINAR MAS GROUP – Greenpeace Report. You can also Google: Greenpeace papering over corporate control paper excellence for the 70-page compressive report or see the attachment! Greenpeace report provides their readers with a very good understanding of China and Indonesia manufacturers business deals that is a must to read. We will highlight some of the key points below with a focus on Paper Excellence estimated at $12 billons plus acquisitions and the big question is where the money is coming from and the impact on the USA Paper, Pulp, Converting, Forestry, Nonwovens and supporting industries!

Key Points in the report!

Set to talk about her decades in industry and the debut of her e-book 14 Dinners and a Lunch, Susan Stansbury will speak in Green Bay August 30. “Her career is unique with so many assignments as the lone woman in management, and with her breadth of experience,” says Marty Ochs of Green Bay Innovation Group, co-sponsor along with Women in the 5P group. 5P chairs Cassie Diedrick and Emily Haines will act as co-hosts.

“While I did not set out to work in the manufacturing world back in the 70s, the markets and incidents along the way are the stories of my book,” says Stansbury. “I used 14 Dinners and a Lunch as occasions to reveal certain happenings and surrounding times; I was often determined, sometimes distressed, occasionally amusing. I kept many of the details to myself, believing in evolution, not revolution.” Her August 30 speech will include comments on business methods and mechanisms that led to career growth.

A skilled speaker, Stansbury has been a presenter for many years at industry conferences throughout the U.S. as well as in Europe. She plans to include some strategies that served her well during her career. Her working career included jobs at major paper producers, specialty work on healthcare products, flexographic printing, and packaging. She had stints leading a quality process, strategic planning, and product development. During the pandemic, she worked on mask and wipes products as well as materials sourcing. She also originated and owned the Converters Expo at Lambeau for several years. More recently she consulted with clients across the U.S.

Hosts for the Green Bay event:

Diedrick and Robinson represent today’s Women in the 5P (Packaging, Printing, Paper, Pulp, Plastics). They will lead with questions after the speech.

For more information about Stansbury’s book release, contact via email: Details@14Dinners.com. Susan R. Stansbury’s short bio is on LinkedIn.

The Green Bay Innovation Group netted $15,000 from our SWING BIG with GBIG Golf Outing in 2023. We will be donating ALL the proceeds to food pantries, homeless shelters, and other non-profit organizations. We want to thank our one hundred fifty golfers, twenty-six sponsors and all of you for providing additional donations and gifts supporting the event.

The mission statement of the Green Bay Innovation Group is to bring together and create opportunities. for networking between Wisconsin companies involved in the Paper, Printing, Pulp, Plastics, Packaging, Converting and Supplier Industries! GBIG creates an open dialog between companies. At GBIG webinars and meetings, we talk about current and new products, technology, innovation, sales, marketing, and social media/web design and new equipment. GBIG is looking to create new products, new markets and expand the presence of our industries in Wisconsin. We are here to help you push the norm and Challenge one another to help make our companies and our communities better! Finally, we are bringing financial support to our communities, especially to those most in need through the donations from our Sponsors!

On September 26, learn about the businesses that set the region apart for its manufacturing strengths. From printers to paper, plastics, and roll goods converters, this Showcase event expands in its second year. Hosted by Green Bay Innovation Group (GBIG), the full day takes place at Green Bay’s Radisson Hotel & Conference Center.

“This expo features companies with industry updates in several categories and provides outstanding networking opportunities,” says Marty Ochs of GBIG. “We live at the center of innovation, technology, and production capabilities. We have planned for a larger expo and visitor attendance this year.”

Aspects include:

“We plan to spotlight exceptional exhibitors as they come back this September, and we’re offering a forum for new companies coming on board,” says Susan Stansbury co-host. “You can find these companies at national shows, but they appreciate showing off their wares in their home territory. This area is ‘the converting corridor.’”

Notes Marty Ochs, “Over the next couple of months, we will be reporting on a cross-section of exhibitors and plans, including a keynote speaker from the Flexible Packaging Association. In addition, a panel of other speakers on innovation is on board.”

The location at the Radisson Hotel and Conference Center represents an expanded space for exhibitors. The cost to attend for the day is $50.00 including lunch and refreshments. The Expo Hall will be open from 9:00 a.m. to 4:00 p.m. followed by networking until 6:00 p.m.

Look for more news to come.

Interested attendees can sign up at: www.GreenBayInnovationGroup.com and go to EVENTS to register.

To exhibit, call or email: Marty Ochs, GBIG, 608.698.3333 martinpochs@gmail.com

Susan Stansbury, Industry Consultant, 920.265.6407 SusanRStansbury@gmail.com

This event is hosted by Green Bay Innovation Group, providing news and platforms for paper, packaging, printing, plastics, and converting industries.

Hurckman Mechanical Industries (HMI) is proud to announce a significant safety milestone as they reach one million hours without any lost time incidents. This achievement highlights HMI’s commitment to creating a safe work environment and marks a significant step toward establishing a strong safety culture within the company. HMI has also achieved a remarkably low EMR (Experience Modification Rate) and TRIR (Total Recordable Incident Rate) numbers, solidifying their position as one of the safest mechanical contracting companies in the Green Bay area. At HMI, safety is the responsibility of every employee, from top management to the individual worker.

HMI would like to take this opportunity to express their gratitude to Marty at the Green Bay Innovation Group (GBIG) organization for their invaluable support. The association with GBIG has been highly beneficial, and HMI looks forward to continuing their partnership with this esteemed organization.

As a family-owned business, with 70 years of experience specializing in commercial and industrial Plumbing, HVAC, Piping, Insulation, Sheet Metal, and Refrigeration services, HMI has built a strong reputation for innovation, efficiency, and customer satisfaction. With a moto of “No Empty Promises,” the company strives to deliver end-to-end solutions, from project management to ongoing support, while prioritizing long-term client relationships. By embracing excellence and a forward-thinking approach, HMI has become a trusted partner in providing high-quality mechanical services. HMI is committed to maintaining its position as a leader in the mechanical contracting industry.

On June 20 th , 2023, the Wisconsin Paper Council (WPC) held its Annual Meeting at Lambeau Field in Green Bay, Wisconsin. This event had a turnout of around 100 attendees that included paper industry professionals, supply chain businesses, workforce development agencies, and community organizations. Thank you to our Annual Meeting sponsors and exposition participants for making this year’s meeting a success.

The meeting began with introductions and the announcement of a new scholarship initiative for women in the forest products industry. This scholarship is intended to support Wisconsin women coming out of high school who want to enter the forest products industry, as well as fund women currently in the forest products industry who want to further their education. The scholarship has been established with an initial gift of $20,000 from Ahlstrom.

“Ahlstrom recognizes the need to have more women in the paper industry and this scholarship is designed to encourage high school young women to enter different fields in the paper and forest products industries, and to encourage women leaders already in the field to grow their leadership skills through education,” said Addie Teeters, Head of Marketing Communications & Public Affairs for Ahlstrom, and current Vice Chair of the Wisconsin Paper Council Board of Directors. “The forest products industry is an innovative and strong industry, and we need to empower our diverse voices and encourage unique talent to join us.”

Applications will open early 2024 and scholarships will be awarded Spring 2024. WPC challenges other companies to donate to the scholarship fund, but individuals can also contribute. The scholarship is housed by the Women’s Fund for the Fox Valley Region and donations can be made here: https://cffvr.fcsuite.com/erp/donate/create/fund?funit_id=4663&sorg_id=1002.

WPC staff provided updates on successes, initiatives, and committee information. President Scott Suder announced that the USDA Forest Service Wood Innovations Grant has been awarded to WIST in partnership with WPC. Vice-President of Environmental and Regulatory Affairs & General Counsel Patrick Stevens provided updates ways in which WPC is involved with regulation in the environmental front.

Director of Operations Shawn Brantmeier announced the upcoming WPC Women’s Leadership Adventure Series intended to connect women in the forest products industry together and provide education on leadership skills. Another initiative aimed at breaking barriers for women in the traditionally male-dominated field is the Women’s Leadership Conference in coordination with Mid-State Technical College. This event will occur Spring 2024 and more information is coming soon.

Communications & Development Analyst Mykaela Chaffin announced the progress of WPC’s new Workforce Relations Committee, the success of the annual WPC Sustainability Report, and the opportunities available for members through the WPC podcast, The Paper Files. Information on the Sustainability Report and The Paper Files can be found on WPC’s website, www.wipaper.org.

In lieu of a singular keynote speaker, WPC hosted a panel of industry experts to discuss sustainability, talent attraction, and economics. Panelists included:

Thank you to our panelists for providing insight on the paper, pulp, and packaging industry!

WPC looks forward to next year’s annual meeting, as well as our upcoming Golf Outing on October 3rd, 2023 at Bullseye Golf Club in Wisconsin Rapids. For questions or comments, please contact Mykaela Chaffin at chaffin@wipaper.org.

Nuclear gamma backscatter sensors have been used in the past for making product weight measurements in coating applications due to their ability to do so no matter the coating type and provide accurate readings of coating weight. However, these sensors come with several limitations that hinder their effectiveness in this application.

Firstly, they pose significant safety concerns due to their radioactive nature, which can result in health hazards if not handled correctly. Secondly, nuclear isotopes have an effective lifespan due to the half-life of the isotope used. This leads to the need for replacing the source material and disposing of the old source material, and this can be costly. Additionally, these sensors require significant maintenance and calibration to keep them functioning correctly. This adds to the overall cost of using them. As a result, many companies have shifted to using non-nuclear sensors such as near infrared methods for measuring coating thickness.

Introducing near infrared (NIR) gauging system for coating thickness measurement is a game-changer. This technology allows for accurate and real-time measurements of coating thickness across various substrates. With the help of the NIR gauging system, variations in coating thickness can be identified and remedied, ensuring the production of uniformly coated surfaces.

If you are in the business of measuring coating thickness for converting web-based applications, you might be using nuclear gamma backscatter sensors to achieve precise measurements. However, these methods have some limitations and potential safety concerns.

Nuclear-based sensors, for instance, use radioactive isotopes to measure coating thickness. This method presents several limitations, including regulatory and safety requirements in handling radioactive materials, the need for trained personnel, and the risk of contamination.

A safer and more reliable alternative to nuclear gamma backscatter sensors is using a near infrared (NIR) gauging system. This technology utilizes light waves in the near-infrared spectrum to measure coating thickness, offering several benefits for accurate cross-web distribution profiling.

Safer and Easier Operation

NIR gauging systems are safer and easier to operate since they do not require radiation sources. The instruments can be easily integrated into your production line, and calibration can be quickly adjusted. This allows for smoother operations, fewer safety measures, and greater process efficiencies.

Non-contact Measurement

NIR gauging systems offer an excellent solution for non-contact measurement of coating thickness. Without touching or impacting the coated surface, the system can measure the coating thickness for flexible substrates, flat substrates, and individual sheets with consistent, defect-free results.

Real-time Measurement

The NIR gauging system can measure coatings in real-time, allowing for immediate monitoring of any variations in coating thickness and quick adjustments to maintain the desired thickness levels.

Complex Surface Capabilities

The system can accurately measure the thickness of coatings on complex surfaces, making it suitable for coating applications that might require specialized rolls, extrusion coating, or gravure coaters.

Cost-effective Alternative

NIR gauging systems offer a more cost-effective solution for thickness measurement than nuclear-based or other alternative measurement methods. The system reduces the cost of maintenance that results from radioactive disposal and significantly reduces the training time required for personnel to use the equipment.

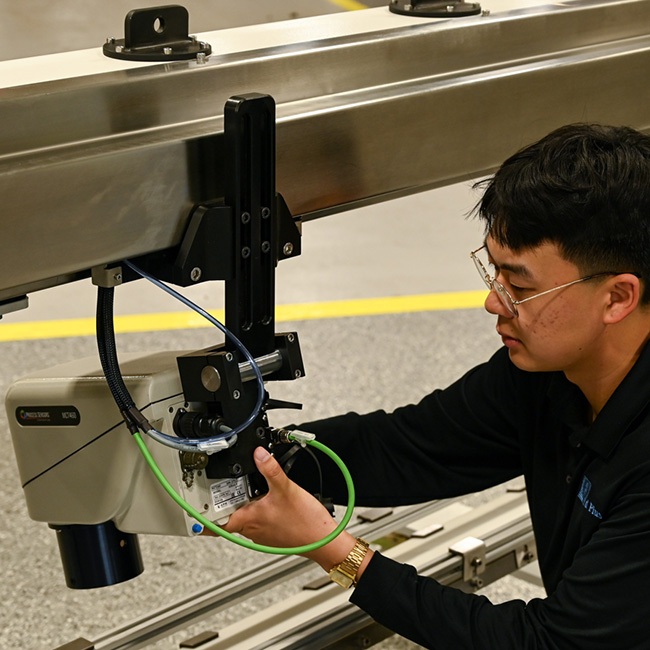

Quad Plus helped a coating company upgrade their nuclear-based coating gauge system. The old system had problems like poor roll gap control and limited data points. The upgrade to a near-infrared gauging system solved these issues. Quad Plus removed the nuclear sensors safely and in compliance with regulations. They supplied and installed a new scanning gauge system that implemented roll gap control. The new system improved safety and allowed for accurate measurements of cross-web distribution and coating thickness control. Quad Plus’ expertise and advanced technology helped the client achieve better results.

Measuring coating thickness is crucial for ensuring product quality and consistency in a cost effective and safe manner. The advantages of using an NIR gauging system versus nuclear gamma backscatter sensors include improved safety, consistent performance, real-time monitoring, reduced cost, and greater versatility in measuring complex surfaces.

For assistance with replacing your nuclear gamma backscatter gauging system, please contact Jim Woulf at Quad Plus. You can reach him at (920) 515-4155 or via email at jwoulf@quadplus.com.

Bringing Green Bay Companies Together. Green Bay Innovation Group is committed to building an authentic networking experience where innovation can thrive.

© 2021 Green Bay Innovation Group

Site By: Packerland Websites