Read the May 28th, 2025 Green Bay Innovation Group Newsletter here.

Read the May 28th, 2025 Green Bay Innovation Group Newsletter here.

The Swing Big with GBIG has room for 216 Golfers and 54 Hole Sponsors! We have registered 200 Golfers and 44 Hole Sponsors. The Swing Big with GBIG is on June 19th at Mid Valley Golf Course in De Pere, Wisconsin.

We are expecting over 375 people to attend the event! We have a FREE NETWORKING EVENT after 4:00 p.m. so join us for this outstanding outing. The golf outing is the largest Industry event in the Midwest!

The cost for individual golfers is $150.00 or a Foursome for $600.00. The hole sponsorship is $300.00.

We have room for just 216 golfers!

Go to: www.greenbayinnovationgroup.com/events – Swing Big with GBIG to register.

Get links to the latest news, events, stories, and interviews from our 5P news members. Our goal is to remind the decision-makers in Wisconsin of the importance of our industry both historically, and more importantly, into the future.

Read the latest 92 Stories and Links on the Internet below.

Midwest manufacturing isn’t short on grit, experience, or capability. But when it comes to consistent, scalable growth, even the most capable leaders can find themselves stuck.

You’ve invested in new tools and systems. You’ve restructured teams. You’ve refreshed the brand and upgraded the website—maybe more than once. But just when revenue should be accelerating, it stalls. The harder you push, the more frustrating it gets.

This isn’t a lack of effort. It’s a structural challenge—one we at Stoke RGA know well.

Here’s how it usually plays out: Leadership calls for more growth. Marketing turns up the volume—campaigns, content, ads. Sales gets flooded with unqualified leads and tunes them out. Operations scrambles when something does close. Next quarter? The same conversation repeats:

“Why are we still not growing?”

It’s not a lack of strategy—it’s a lack of cohesion.

Disconnected tools, tactics, and teams create noise, not momentum. We call this the Growth Insanity Cycle—repeating the same moves month after month, expecting different results.

Rebranding, redesigning, and refreshing your digital presence are important milestones. But without a way to unify and activate them, they’re just that—milestones.

Great creativity deserves more than visibility. It needs to be plugged into a revenue engine that connects your brand story to your sales process, aligns your teams, and fuels performance at every stage.

That’s where most manufacturers fall short—not in effort, but in alignment.

At Stoke RGA (Revenue Growth Accelerator), we help Midwest manufacturers break free from the Growth Insanity Cycle by embedding a revenue architecture that’s designed to scale.

We’re not consultants who hand over a deck and disappear. We stay in the trenches—aligning teams, building infrastructure, and driving execution.

Our approach is hands-on, data-driven, and built for real-world conditions—plant floors, boardrooms, and everywhere in between.

We’ve helped manufacturers:

These aren’t just marketing wins. They’re business transformations—achieved through a connected approach that removes friction and amplifies results.

Growth plateaus don’t come from a lack of ambition—they come from gaps in how the business operates as a whole. That’s why we built the Revenue Growth Accelerator: a five-stage framework tailored specifically for $75M+ Midwest manufacturers.

Most firms deliver ideas. We deliver outcomes.

We don’t hand you a strategy and hope it works. We work shoulder-to-shoulder with your people—on the floor, in the meetings, across departments—to make sure it does.

With Stoke RGA, you get:

That’s the Stoke RGA difference. Strategic where it matters. In the trenches where it counts.

This is where we walk through how Stoke RGA helps manufacturers move from stalled to scalable—live and unfiltered.

Inside The Briefing Room, we break down the Revenue Growth Accelerator, share real-world case studies, and show how we turn commercial complexity into momentum.

We believe in the future of Midwest manufacturing. And we know the companies that will lead it won’t get there by chasing tactics—they’ll get there by building something better.

Let’s break the cycle. Let’s build what’s next.

The Green Bay Innovation Group would like to thank ALL our CONSTRUCTION COMPANIES for their Sponsorship and Support: Boldt, CR Meyer, Hoffman Construction, Hurckman Mechanical Industries, Keller Inc., Miron Construction, IMMEL, SMET Construction Services, and Alliance Construction.

We recognize their impact not just in Wisconsin but across the USA. The Boldt Company is the 14th largest Construction Company reaching $5 Billion and Miron Construction Company reaching $1.76 Billion at the 28th spot based upon a report from Building Design & Construction. Wisconsin has a large concentration of Construction Companies located in Northeastern Wisconsin!

The construction industry drives growth and provides high paying jobs producing $20.8 billion in annualized nominal GDG Q3 2024 accounting for 4.6% of the total state GDP. Employment in industry increased 2.8% to 142,000 in December 2024. With the average annual wages in the industry at $76, 391.

The economic impact of the Construction Industry has the following multiplier effects within the State of Wisconsin.

We are witnessing tremendous growth in the Food, Packaging, Flexible Packaging, Plastics, Corrugated, and the Converting Industries. Wisconsin is a leader in the USA in all these categories.

The Green Bay Innovation Group is putting together accurate information, databases, and reports to provide a better understanding of the impact of these sectors of the Wisconsin Economy. Our goal is to provide support and help companies make better decisions, find new business opportunities for their companies in the 5P and Converting Industries!

The Green Bay Innovation Group is a Business-to-Business Non-Profit Foundation. Go to: www.greenbayinnovationgroup.com/events – Membership to become a Members!

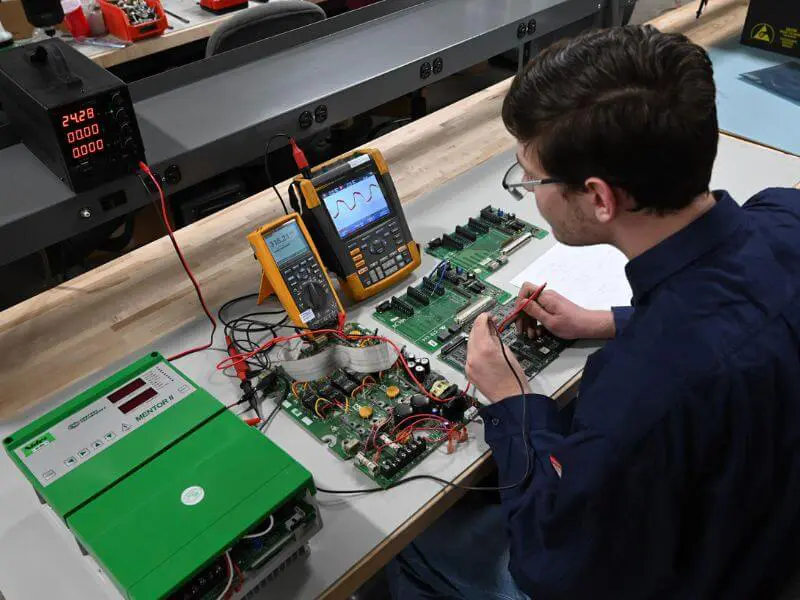

Industrial operations depend heavily on the performance and reliability of electrical systems, and among the most critical components is the variable frequency drive (VFD). These drives regulate motor speed and torque, improving energy efficiency and extending motor life.

However, like any equipment, VFDs can degrade over time. Without timely repair, their failure can lead to costly downtime, safety hazards, and reduced productivity.

A variable frequency drive is an electronic device that adjusts the speed and voltage supplied to an electric motor. VFDs enable precise control over motor functions to reduce energy waste and mechanical stress, supporting smoother operations and longer equipment lifespan. They also include control circuitry for feedback, fault detection, and integration with programmable logic controllers (PLCs) and industrial networks.

VFDs are commonly used in HVAC systems, conveyor belts, pumps, and other motor-driven equipment where speed variability is crucial.

Routine maintenance is essential for all equipment, but variable frequency drive repair becomes critical when warning signs such as overheating, erratic motor performance, or alarm codes appear. Timely repair prevents cascading failures in connected systems and avoids the high cost of full replacement.

Skilled repair services can restore drives to optimal function, recalibrate settings, and replace worn components while maintaining original equipment specifications.

VFD repair isn’t just about performance. It is also a key part of maintaining a safe, compliant workplace. Standards like OSHA 1910 and ISO 45001 require that electrical systems be regularly inspected and maintained to reduce the risk fo shock, arc flash, and equipment malfunction. When drives overheat or fail unpredictably, the result can be anything from a line shutdown to a serious safety incident.

Proper maintenance and timely repairs reduce these risks. A well-functioning VFD supports stable motor control, allows for safer emergency stops, and integrates more effectively with modern safety interlocks and monitoring systems.

Downtime in industrial operations can cost thousands of dollars per hour. Proactive variable frequency drive repair services reduce unplanned outages and contribute to leaner operations. A single VFD failure can stall an entire production line. Prioritizing repairs will help stabilize operations, avoid emergency service calls, and support planned maintenance cycles.

Variable frequency drives are often exposed to harsh industrial conditions, including heat, dust, vibration, and electrical noise. These factors can accelerate wear on capacitors, cooling fans, and circuit boards.

Understanding how environmental stress impacts VFD performance allows for better preventive maintenance and repair planning. For example, facilities with high ambient temperatures may need to closely monitor thermal protection systems or schedule more frequent inspections.

Additionally, drives used in applications with frequent starts, stops, or load variations are more prone to component fatigue. By accounting for these stressors in repair protocols, facilities can improve drive longevity and ensure stable, compliant operations across various conditions.

VFDs are vital for efficient, safe, and sustainable industrial operations. Regular repairs and adherence to safety standards protects workers and safeguard equipment and production goals. Investing in expert repair services now can save far more in future replacement costs and lost productivity.

To learn more about maintaining and repairing VFDs and how they impact your operations, contact Adam Kahler at akahler@quadplus.com or call (815) 210-9885.

Quad Plus – www.quadplus.com

1379 Unit C Carlson Ave New Richmond, WI 54017

Digital printing in the label market is coming of age. Today, a significant proportion of label converters are running digital or digital hybrid label printing presses alongside their established flexo equipment, with digital accounting for 21.6% of the market value of labels produced globally in 2024.

While digital printing technology’s versatility and efficiency for short print runs have been a key driver for growth for many printing businesses, feedback from many converters underscores the importance of retaining access to both digital and flexo technologies.

Balancing customer demand for sophisticated label design and finish with workload, capacity, and productivity means that converters now need to be able to evaluate and respond to a variety of operational scenarios; the choice of digital, hybrid, and flexo technology is no longer down to print run length alone.

Mike Barry, Commercial Manager – Digital Printing, Domino Printing Sciences, explores the considerations and challenges for converters looking to maximize the return on their label printing assets while meeting their brand customers’ needs.

The choice of whether to use flexo, digital, or hybrid print technology has, until now, primarily come down to application and run length, with long, low-variation print runs typically the

domain of flexo, and shorter, higher-variation print runs allocated to digital.

However, the common conception that once the print volume of a label has grown to a certain level (with the figure varying depending on who you ask), it will be more efficient and profitable to move from digital to hybrid and hybrid to flexo is no longer holding true. For most converters, the crossover point between technologies is not fixed; rather, it is continuously shifting to reflect changing customer demands and press availability from day to day and job to job. Indeed, sticking to a rigid limit based on print volume alone can adversely impact overall operational efficiency and resource utilization. Moreover, failure to embrace flexibility in print technology allocation – e.g. running a job on whichever press is available at the time – may even necessitate declining a project, to the detriment of client relationships and brand reputation.

This drive for operational efficiency is, at least in part, driving the increase in hybrid printing

sales – which, according to market research reports, is projected to grow at a compound annual growth rate (CAGR) of around 12%, surpassing a valuation of around USD 16.53 billion by 2034. In practice, many converters are now taking advantage of the flexibility of their hybrid lines to help balance their overall workload, pushing hybrid volumes as high or as low as their business requires.

So, how can converters achieve the optimal balance between flexo, digital, and hybrid printing?

Maximizing press run time remains a key consideration for converters: the simple maths is that any downtime reduces ROI. However, in a print production facility with multiple technologies, considering individual press run time in isolation may be missing the bigger picture.

For example, let’s consider the idle time of the digital asset on a hybrid press during flexo station set-up. A short-run job encompassing digital printing, embellishments, and finishing could be produced in a single pass on a hybrid press – but it may be worthwhile using a separate digital label printing press for some elements of the job, with the finishing aspects covered offline in a second step. Deploying a solution like this will maximize the return on the digital press with near continuous running, compared to introducing periods of downtime on the digital print module in a hybrid line during flexo station set-up.

Similarly, being able to move shorter runs from flexo or hybrid presses to digital-only solutions can provide converters with an instant productivity increase, freeing up hybrid or flexo press capability for longer, more profitable runs, with less time and consumable waste incurred during set-up and changeovers.

Then, let’s consider multi-SKU jobs. At first glance, digital technology should be the best way to manage such variations. However, if the labels share the same die and varnish with only minor artwork variations or variable data elements – such as language versions of a standard label – hybrid could be a more efficient choice. In this scenario, if large areas of the label are ‘standard’, a converter using a hybrid solution will only incur the set-up time of the analogue part of the press once, spreading it across multiple jobs, increasing productivity, and lowering job cost. Flexo stations on a hybrid line can also offer more effective application of bold, solid colors, enabling potential cost reductions compared to digital printing alone, as well as enhancing appearance.

Ultimately, it is up to the converter to decide which option will deliver the best overall ROI, considering all the variations, other jobs being processed, and the availability of labor to oversee each step.

While transitioning between digital, hybrid, and flexo technology to meet business demands may make operational and commercial sense in some scenarios, converters also need to consider their ability to manage these transitions smoothly, both in the moment and over the time span of a particular client’s job.

For example, ensuring image quality and brand color consistency across platforms can be a

challenge when brand customers request a low-volume run to re-stock an existing SKU, as moving artwork from a flexo to a digital label printing process typically does not deliver the same result.

Flexo spot colors in a hybrid label printing process may seem an obvious choice for color sensitive jobs, as the brand elements of color are rarely – if ever – changed between product variant runs, with little flexibility lost when running a set of similar but not identical labels on a hybrid press.

However, even spot colors can be subject to color matching challenges as heat and mechanical factors such as pressure can cause subtle color variations, with some converters reporting 10 to 15 percent of a run being rejected due to color inconsistencies.

Aware of this issue, more and more converters are turning to digital inkjet printing technology to help ensure color consistency and image quality, selecting a digital label printing press even for jobs with ‘flexo’ run lengths because the color consistency and image quality are overall better and more consistent.

Until packaging designers can anticipate potential variability in the label printing process and technology used so that results are consistent across both flexo and digital print, the onus lies on the converter to decide whether brand, cost, or maximizing operational capacity is the more important factor.

Clearly, there is no one-size-fits-all approach, nor is there a universal cut-off print run volume between technologies. Indeed, flexo, hybrid, and digital solutions all have an equal part to play in a converter’s optimal operating efficiency – and long-term competitiveness will likely depend upon having the right combination of presses to meet current and evolving business demands.

A strong solutions partner at the forefront of printing innovation will be able to help converters evaluate how to allocate print jobs to maximize uptime and productivity across their operations, as well as supporting in the long term through genuine appraisal of current workload and future opportunities to determine the best solution for their business.

Disclaimers

Inks

The information contained in this document is not intended as a substitute for undertaking appropriate testing for your specific use and circumstances. Neither Domino UK Limited nor any of Domino’s group of companies is in any way liable for any reliance that you may put on this document with regards to the suitability of any ink for your particular application. This document does not form part of any terms and conditions between you and Domino, Legal

Disclaimers v.1.0 February 2018 and Domino’s Terms and Conditions of sale, and in particular the warranties and liabilities contained within them, shall apply to any purchase of products by you.

General

Information contained within this press release is considered to be true and correct at the date of publication by Domino, changes in circumstances after the time of publication may impact the accuracy of the information. All performance related figures and claims quoted in this document were obtained under specific conditions and may only be replicated under similar conditions. For specific product details, you should contact your Domino Sales Advisor. This document does not form part of any terms and conditions between you and Domino.

Imagery

Images may include optional extras or upgrades. Print quality may differ depending on consumables, printer, substrates, and other factors. Images and photographs do not form any part of any terms and conditions between you and Domino.

Videos

This video is illustrative only and may include optional extras. Performance figures obtained under specific conditions; individual performance may vary. Errors and downtime on production lines may be unavoidable. Nothing in this video forms part of any contract between you and Domino.

Notes to Editors:

Digital Printing Solutions is a division within Domino Printing Sciences. The company, founded in 1978, has established a global reputation for the development and manufacture of digital inkjet printing technologies, as well as its worldwide aftermarket products and customer services. Its services for the commercial print sector include digital inkjet printers and control systems designed to deliver solutions for a complete range of labelling, corrugated, and variable printing applications.

All of Domino’s printers are designed to meet the high-speed, high-quality demands of commercial printing environments, bringing new capabilities to numerous sectors, including labelling, corrugated, publications and security printing, transactional, packaging converting, plastic cards, tickets, game cards and forms, as well as the direct mail and postal sectors.

Domino employs over 3,000 people worldwide and sells to more than 120 countries through a global network of 29 subsidiary offices and more than 200 distributors. Domino’s manufacturing facilities are located in China, Germany, India, Sweden, Switzerland, UK, and the USA.

Domino became an autonomous division within Brother Industries Ltd. on 11th June 2015.

For further information on Domino, please visit www.domino-printing.com

For more information, please contact:

Kathrin Farr

Content Executive and Copywriter

Domino Printing Sciences

Tel: +44 (0) 1954 782551

Kathrin.Farr@domino-uk.com

Alex Challinor

PR and Content Manager

Domino Printing Sciences

Tel. : +44 (0) 1954 782 551

Alex.Challinor@domino-uk.com

Green Bay, WI — The Wisconsin Paper Council (WPC) will hold its 2025 Annual Meeting on Tuesday, June 24, at Lambeau Field in Green Bay. This is the WPC’s largest networking event of the year and will feature expert panel discussions on industry innovation and safety best practices. In addition, the meeting will include a Paper Hall of Fame induction ceremony and unveiling of the Women in Forest Products Industry Scholarship recipients.

“Our Annual Meeting is the perfect opportunity for everyone in the forest products industry to get together to network, exchange new information & ideas and have a little fun in the process,” stated WPC Director of Operations Shawn Brantmeier. “Our event is open to both WPC member and non-members and will also feature numerous vendor expo displays. ”

Register to attend: Click Here

Registration includes breakfast, lunch, beverages, and a walking networking tour of Lambeau Field.

Become a sponsor: Click Here

Apply to be a vendor: Click Here

The WPC Annual Meeting is a great opportunity to stay connected, learn about current issues, and support Wisconsin’s paper industry – – all in one legendary location.

The Wisconsin Paper Council (WPC) is the member-driven statewide trade association representing Wisconsin’s paper, pulp, packaging and forestry industries. The WPC strategically advocates on behalf of these industries to state and federal policymakers, achieving positive policy outcomes.

The WPC provides world class educational forums and networking opportunities for our membership. The WPC also promotes the positive economic, environmental, and social contributions of our industries throughout our state and nation.

Read the May 21st, 2025 Green Bay Innovation Group Newsletter here.

The SWING BIG with GBIG GOLF OUTING IS ON JUNE 19th at the Mid Vallee Golf Course 3850 Mid Valley Drive, De Pere, WI. We have room for 216 golfers and 54 Hole Sponsors! We already have 170 Golfers signed up and 42 Hole Sponsors confirmed! We ask you to sign up as soon as you can for this outstanding golf outing. We do have a FREE NETWORKING EVENT starting at 4:00 p.m. open to all of you with room for one hundred additional people! We expect to have over 375 people at the event!

Registration includes 18 holes of golf with cart, two drink tickets, and lunch on the course.

Go to: www.greenbayinnovationgroup.com/events – Swing Big with GBIG to sign up. The cost for individual golfers is $150.00 and a Foursome for $600.00. The hole sponsorship is $300.00. The proceeds from this event will be donated to six outstanding non-profits in Wisconsin! If you have any questions, please contact:

Marty Ochs

Executive Director

Green Bay Innovation Group

698-698-3333

martinpochs@gmail.com

Bringing Green Bay Companies Together. Green Bay Innovation Group is committed to building an authentic networking experience where innovation can thrive.

© 2021 Green Bay Innovation Group

Site By: Packerland Websites