GBIG News

Get links to the latest news, events, stories, and interviews from our 5P news members. Our goal is to remind the decision-makers in Wisconsin of the importance of our industry both historically, and more importantly, into the future.

Read the latest 97 Stories and Links on the Internet below.

Featured Stories

- Expansion investments capacity in the USA packaging industry

- Amcor considering to divest North American beverage business

- Dunnage packaging industry with Menasha Corporation as an American leader.

- UW Stout: Wisconsin researchers think 3D printers can revolutionize health care

- Femsa in merger of Bradyplus with Imperial Dade

- Barbara Koldos VP earns economic development certification

- Uline building large warehouse in CT.

- Layoff at LSC and closing at One Touchpoint

- Labelling market is booming worldwide with Wisconsin company as leaders.

- Kimberly-Clark reports best volume growth in five years

- Billerud investing in Escanaba and Quinnesec mills in Michigan

- Georgia-Pacific President and CEO announces retirement

- AI MIT and Duke chemists develop toughest plastics and cut down on plastic waste

- Global plastics crisis explained in 6 charts

- Billerud Advances upgrades in Escanaba and Quinnesec Michigan

- Amcor commitment to hiring and welcoming refugees

- Michigan State University Agricultural College faces layoffs after USAID cuts

- Shoppers to see higher prices from toilet paper to candy as businesses pass on tariff costs

Specialty Paper

- Ahlstrom launches flame resistant facer to enhance fire protection

- Barrier Coatings for packaging markets

- Barrier coated flexible paper packaging market size

- Barrier Coated paper market

- Storaenso guide book to barrier coatings

- Sustainable food packaging ProAmpac butter wrap

- Sustainability legislation drives packaging innovation for recycling

- BiOrgin Specialty paper revolutionary OGR paper for food packaging

Packaging

- Designing Custom Packaging: Key Factors to Consider

- The clean label movement in packaging

- How Dow drives sustainable packaging

- Digital Printing is making inroads in packaging

- Single use packaging market with a projected 6.1% cagr growth rate

- UW Stout Molded Fiber Association awards Students First Place for sustainable packaging solution.

- Why folding cartons are the natural next step for converters

- North America paperboard packaging market

- Paper-Packaging Board marketing USDA program terminated

- Bridging the discipline from labels to flexible packaging

Education

- UW Madison ranks 30th worldwide in our list. Wisconsin legislature need to support education

- The University of Utah could lose $100 million annually for critical research

- UW Green Bay adding Software Engineering

- Trump administration unfreeze billions in education due to public outcry.

- Trump administration cuts UCLA research funds

- UNC announces cuts to federal funding.

- Northwestern to eliminate more than 400 staff positions due financial press due to federal cuts

- The best US Colleges for high paying finance jobs

- Science funding freeze could set research back Harvard

- Harvard endowment could shrink as much as 40% from White House policies

- Trump threatens Harvard over patents worth hundreds of millions of dollars

- Scientists who fled the Nazis built the atomic bomb and lead the world in science. Is the USA going the same direction?

PFAS

- Environment groups, community advocates push for progress on pfas legislation

- This new catalyst destroys forever chemicals within just seconds

- New soybean fighter fighting foam chemical replaces plas from a Wisconsin based company

- Over 73 million people exposed to play in US drinking water

- PFAS UPDATE: States continue to be in the forefront on PFAS products

Plastic

- 27 million tons of nanoplastics discovered in the North Atlantic

- Plastics that melts into nature with no impact on the environment

- Teel Plastics: Medical plastics Extrusion market is booming rapidly

- Scientists unveils bioplastics that degrades at room temperature

- Why are global plastics treaty need to move beyond negotiations

- Can a global treaty solve the plastic problem?

- Microplastics are infiltrating your brain and what are the effects

- Plastics impact on health costs $1.5 trillion every year report warns

- Researchers developed game changing filter that can filter out microplastics

Sponsors

- The McClone Method: The insurance industry is broken

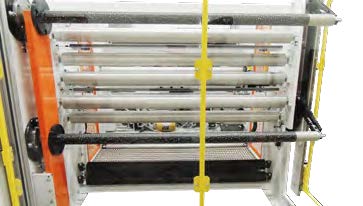

- Voorwood: The leader band Customizing Converting Equipment

- Adhesco Graphics De Pere appoints Chad Atkinson as Business Development Manager for North America

- Wintrust arranges $90 million in financing to Midwest based printing company

- Miron Construction becomes Platinum certified employee friendly workplace

- Fox Valley Wood Products Protecting your Product and Sustainability

- Primient supports sustainable agriculture ingredients