APPLETON, WI – VPI, Inc. is proud to announce that its third annual Tossing for Inclusion Bag Toss Tournament and Fundraiser raised an outstanding $31,000 in support of programs that create opportunities for individuals with disabilities and disadvantages. We thank Green Bay Innovation Group for their support!

The event, held on August 20, brought together around 200 community members, sponsors, and teams for a day of fun, friendly competition, and a shared commitment to building a more inclusive community.

“We are so grateful to everyone who participated, donated, and sponsored this year’s Tossing for Inclusion,” said Tim Riebau, VPI, Inc. president and CEO. “The energy and enthusiasm around this event show how much our community values inclusion and opportunity for all.”

Funds raised will directly support VPI’s mission to foster social, vocational, and economic independence for individuals with disabilities and disadvantages throughout the community.

VPI looks forward to welcoming the community back for the 4th Annual Tossing for Inclusion, scheduled

for Wednesday, August 19, 2026.

For more information about VPI, Inc. and its programs, visit vpiwi.org.

VPI’s mission is to promote the dignity and worth of individuals who have disabilities or are disadvantaged and to assist them in developing their optimum level of social, vocational, and economic independence in the community.

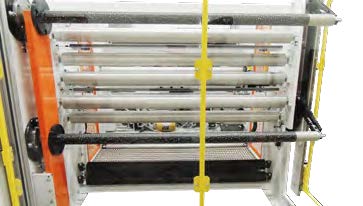

VPI, Inc., a 501(c)(3) non-profit organization, provides a variety of community programs and services including education, early intervention, employment, mental health, and social and recreational services, and packaging solutions to the Fox Cities and surrounding areas. By providing efficient contract packaging and production services to private industry with an integrated workforce, VPI has been able to deliver community programing and services to support the changing needs of community members with disabilities or disadvantages.