The annual event includes daily prize drawings, giveaways, and catered lunch

Stevens Point, Wisconsin (August 9, 2023) – Worzalla, an employee-owned company specializing in printing high-quality children’s books, movie tie-in books and cookbooks, hosted “Worzallapalooza,” its fourth annual month-long event employee appreciation celebration. Throughout the month there were daily cash prize drawings, catered lunch for all, and grand prizes, including grill packages and gift card packages to support local businesses.

“Worzallapalooza has become a tradition that we look forward to every year,” said Brianne Petruzalek, Worzalla Vice President of Human Resources. “We believe it’s important to celebrate and recognize the hard work our associates do and Worzallapalooza is a fun way to do that while also supporting community businesses through our prize offerings.”

Every associate received an ice cream celebration, Worzalla apparel, and an appreciation lunch catered by Canteen Dining. In addition, winners were drawn each day throughout the month for $25 to $500 cash prizes. Three grand prize packages were awarded to Worzalla associates, including Joe Basinski, Tim Pask, and Landon Elgersma.

“As exciting as it is to share with a team member they’ve won, it’s just as exciting to involve team members in the daily drawing,” added Petruzalek. “Team members see us walking around with our drawing bucket filled with names and eagerly volunteer to pick the daily winner.”

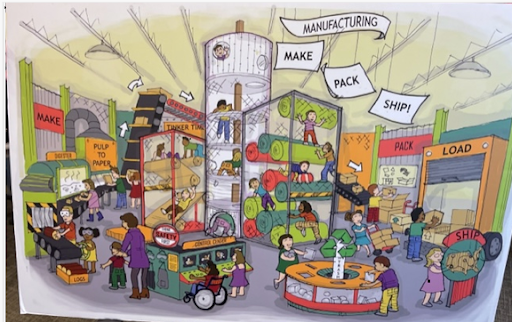

Worzalla currently has several open positions for supervisor, operators, and entry-level roles. Worzalla associates help support printing titles from some of the country’s largest book publishers, including Disney Books, Abrams, Simon and Schuster, Hachette, Penguin Random House, HarperCollins, and others. Worzalla is best known for being the domestic manufacturer of the popular Diary of a Wimpy Kid series. Those interested in learning about a career at Worzalla can visit Worzalla.com.

About Worzalla

Worzalla is an employee-owned printing company headquartered in Stevens Point, Wisconsin. Founded in 1892, Worzalla has over 130 years of experience in creating high-quality custom products for its customers. Worzalla specializes in the production of cookbooks, children’s and lifestyle books, and is dedicated to exceeding expectations for quality, service, and delivery. From small to large publishers, Worzalla is the printer the industry turns to for manufacturing high profile projects and award-winning books. With numerous industry awards for safety and workplace culture, Worzalla is consistently ranked as one of the top places to work in central Wisconsin. For more information, visit www.worzalla.com.

Media Contacts:

Erica Fetherston

10 to 1 Public Relations

erica@10to1pr.com

480-676-9141

Brianne Petruzalek

Worzalla

Vice President of Human Resources

715-254-9717