Nuclear gamma backscatter sensors have been used in the past for making product weight measurements in coating applications due to their ability to do so no matter the coating type and provide accurate readings of coating weight. However, these sensors come with several limitations that hinder their effectiveness in this application.

Firstly, they pose significant safety concerns due to their radioactive nature, which can result in health hazards if not handled correctly. Secondly, nuclear isotopes have an effective lifespan due to the half-life of the isotope used. This leads to the need for replacing the source material and disposing of the old source material, and this can be costly. Additionally, these sensors require significant maintenance and calibration to keep them functioning correctly. This adds to the overall cost of using them. As a result, many companies have shifted to using non-nuclear sensors such as near infrared methods for measuring coating thickness.

Near Infrared (NIR) Gauging System

Introducing near infrared (NIR) gauging system for coating thickness measurement is a game-changer. This technology allows for accurate and real-time measurements of coating thickness across various substrates. With the help of the NIR gauging system, variations in coating thickness can be identified and remedied, ensuring the production of uniformly coated surfaces.

Advantages of NIR gauging system over nuclear gamma backscatter sensors

If you are in the business of measuring coating thickness for converting web-based applications, you might be using nuclear gamma backscatter sensors to achieve precise measurements. However, these methods have some limitations and potential safety concerns.

Nuclear-based sensors, for instance, use radioactive isotopes to measure coating thickness. This method presents several limitations, including regulatory and safety requirements in handling radioactive materials, the need for trained personnel, and the risk of contamination.

A safer and more reliable alternative to nuclear gamma backscatter sensors is using a near infrared (NIR) gauging system. This technology utilizes light waves in the near-infrared spectrum to measure coating thickness, offering several benefits for accurate cross-web distribution profiling.

Safer and Easier Operation

NIR gauging systems are safer and easier to operate since they do not require radiation sources. The instruments can be easily integrated into your production line, and calibration can be quickly adjusted. This allows for smoother operations, fewer safety measures, and greater process efficiencies.

Non-contact Measurement

NIR gauging systems offer an excellent solution for non-contact measurement of coating thickness. Without touching or impacting the coated surface, the system can measure the coating thickness for flexible substrates, flat substrates, and individual sheets with consistent, defect-free results.

Real-time Measurement

The NIR gauging system can measure coatings in real-time, allowing for immediate monitoring of any variations in coating thickness and quick adjustments to maintain the desired thickness levels.

Complex Surface Capabilities

The system can accurately measure the thickness of coatings on complex surfaces, making it suitable for coating applications that might require specialized rolls, extrusion coating, or gravure coaters.

Cost-effective Alternative

NIR gauging systems offer a more cost-effective solution for thickness measurement than nuclear-based or other alternative measurement methods. The system reduces the cost of maintenance that results from radioactive disposal and significantly reduces the training time required for personnel to use the equipment.

Nuclear-based Gauging System Replacement

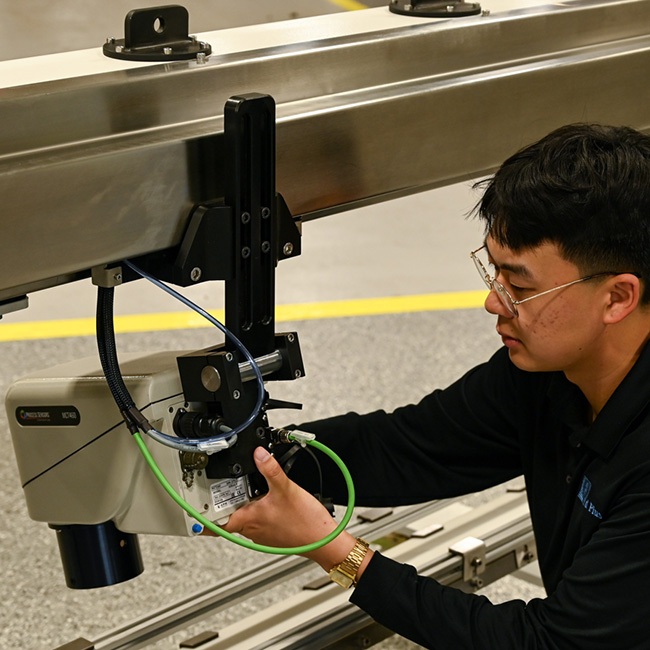

Quad Plus helped a coating company upgrade their nuclear-based coating gauge system. The old system had problems like poor roll gap control and limited data points. The upgrade to a near-infrared gauging system solved these issues. Quad Plus removed the nuclear sensors safely and in compliance with regulations. They supplied and installed a new scanning gauge system that implemented roll gap control. The new system improved safety and allowed for accurate measurements of cross-web distribution and coating thickness control. Quad Plus’ expertise and advanced technology helped the client achieve better results.

Measuring coating thickness is crucial for ensuring product quality and consistency in a cost effective and safe manner. The advantages of using an NIR gauging system versus nuclear gamma backscatter sensors include improved safety, consistent performance, real-time monitoring, reduced cost, and greater versatility in measuring complex surfaces.

For assistance with replacing your nuclear gamma backscatter gauging system, please contact Jim Woulf at Quad Plus. You can reach him at (920) 515-4155 or via email at jwoulf@quadplus.com.